In November of 2023 I acquired another coupe shell by buying a good friend of mine out of his GC project.

Such as these things go, this shell has sat largely untouched since then with basically only some parts collecting and planning contributing to the project.

I'm happy to say, as of a week ago I have made actual forward progress on this project! This marks the first time I've made substantial advancement on any of my personal projects that I actually care about in roughly 4 years. (we aren't going to discuss the fact that the car being worked on here has: A. been owned the shortest amount of time, & B. probably has the least amount of money tied up in it. - lol)

The first stages of this build require some light fabrication work before moving on to paint and body. That's where our story today begins.

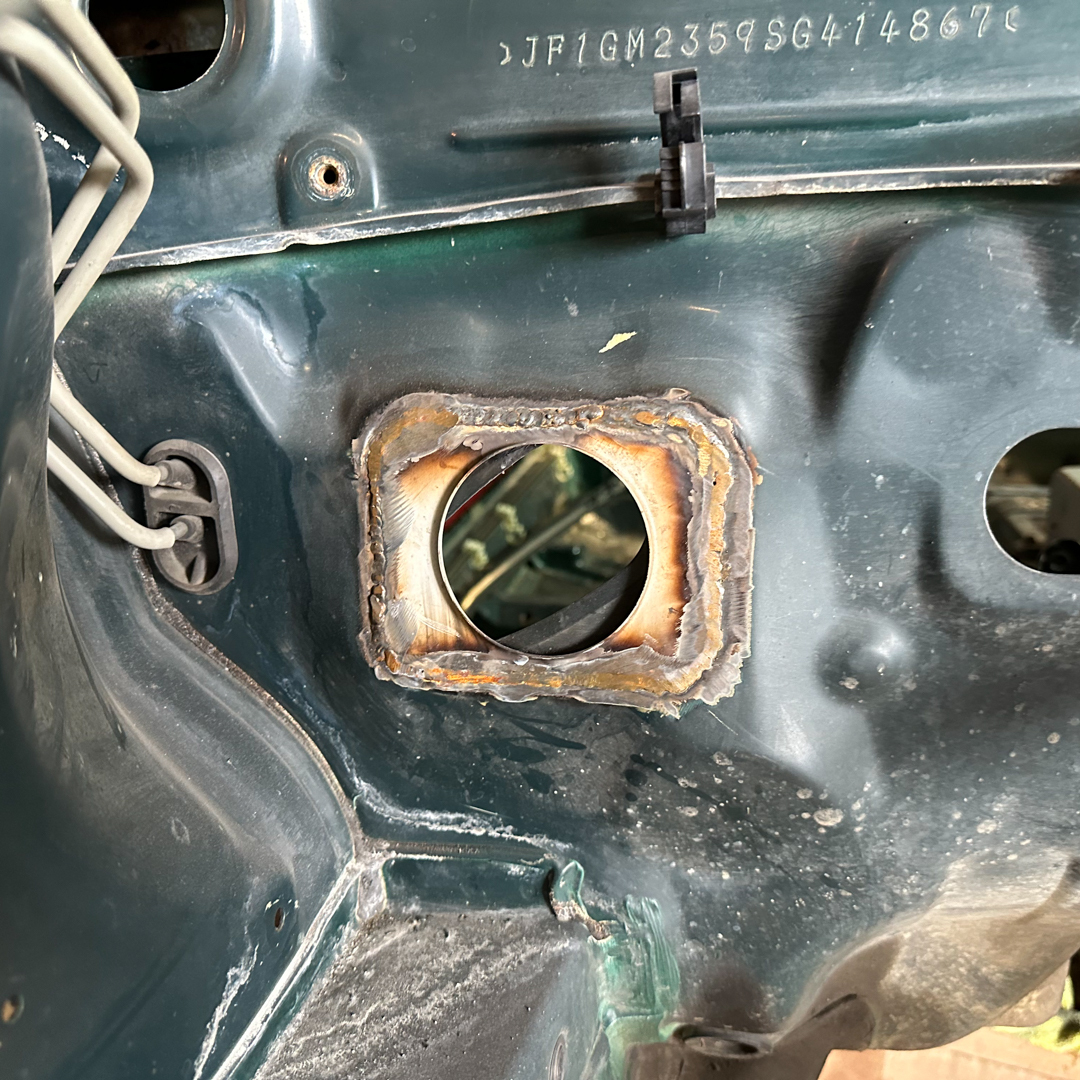

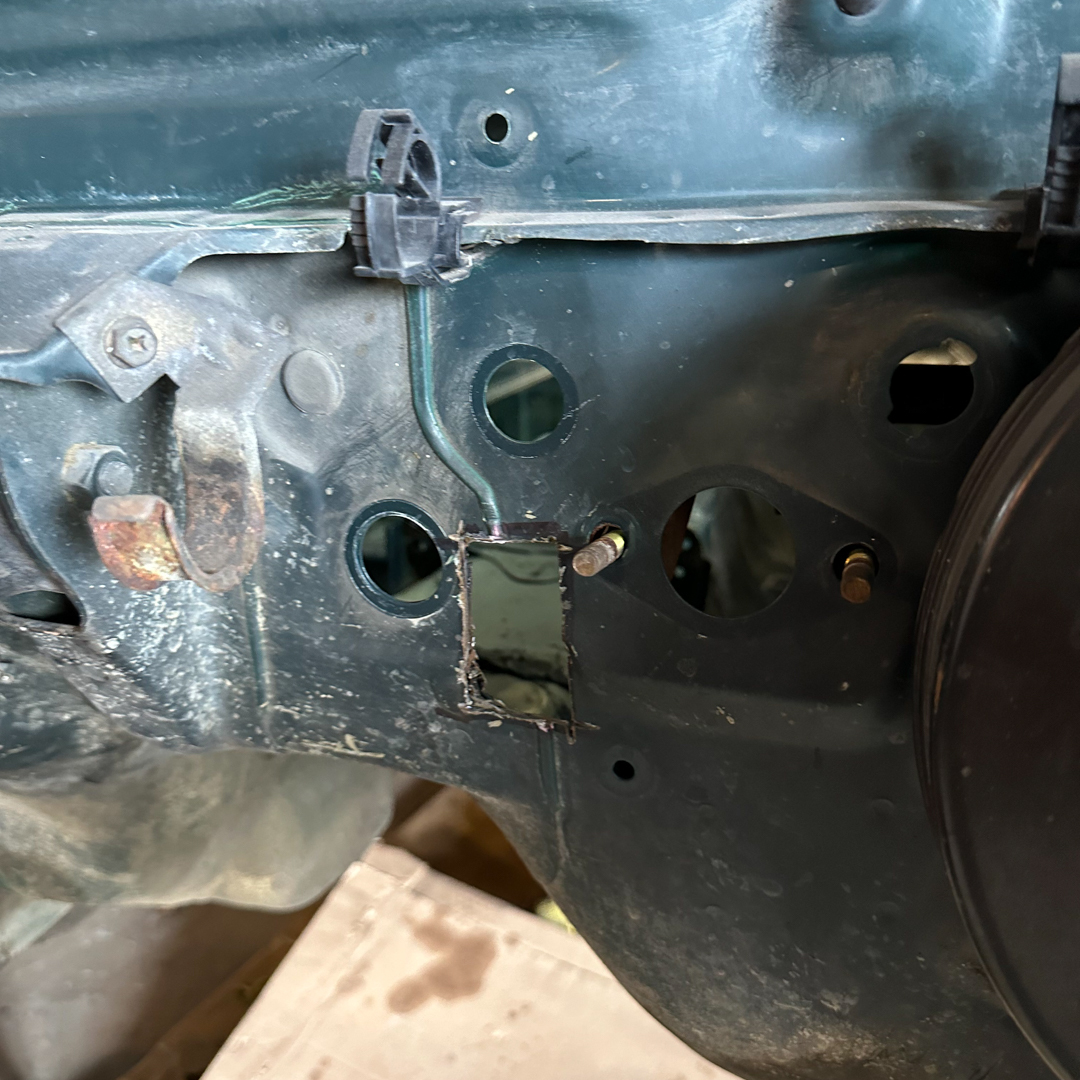

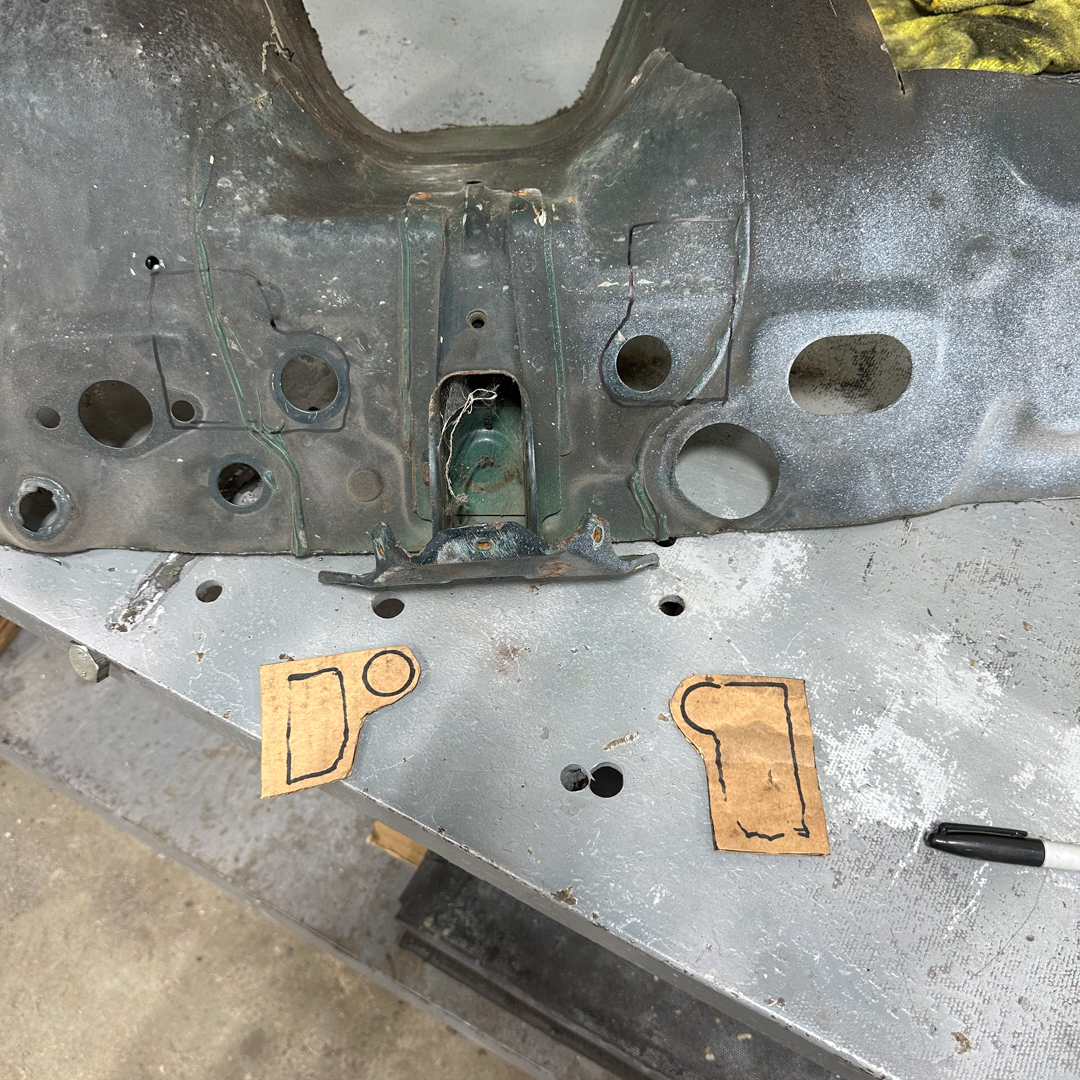

The metal work is in great shape on this car. It is essentially rust free besides some minor surface bubbling around the windshield frame, no major dents or damage, but there were some modifications done to the firewall in preparation for what would have been a GD dash with auto HVAC conversion.

These modifications were:

- A plate welded over the GC AC evaporator port which changes it to support a GD engine wiring harness grommet.

- Two holes cut out of the fire wall to make way for the GD auto HVAC heater core and AC evaporator ports.

I decided that the best way to remedy this would be to get the same section of firewall from a donor car.... So long story short, I bought another shell!

This shell happened to also be a coupe, and the same exact color; it has a rebuilt title and some issues going on with the rear wheel arches so I didn't feel too bad about cutting it up for my needs.

I cut the entire fire wall out with part of the transmission tunnel, and then I decided to take the front clip in front of the strut towers off as well.

My only regret is not cutting out the A pillar to have some sheet metal for antenna deletes in the future.... Oh well, off to the scrap yard she goes!

Now fast forward 4 months, I'm finally feeling motivated to get this repair under way!

I started by grinding down the welds on the plate welded over the AC port, this took a fair bit of work with the flap disc, but was pretty straight forward.

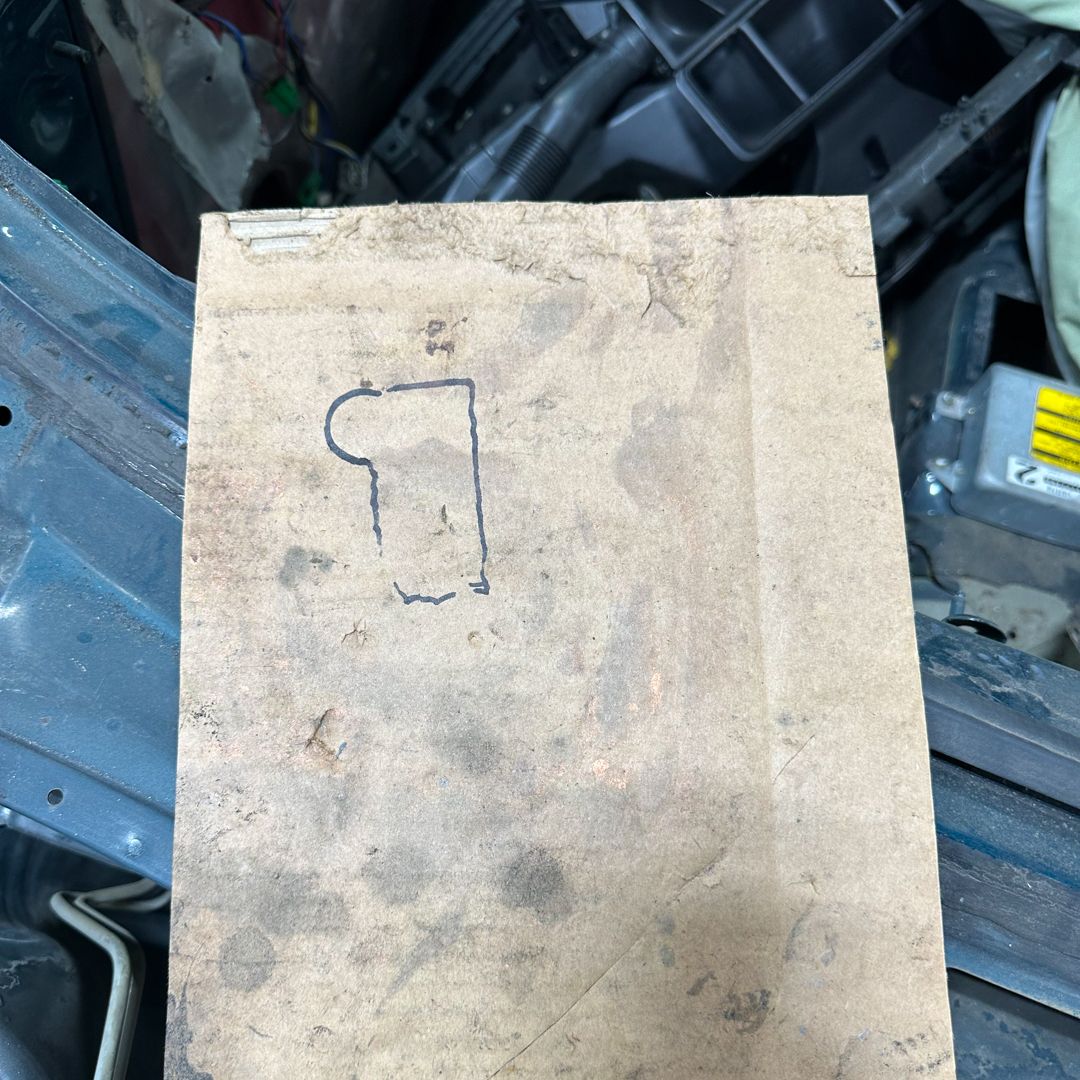

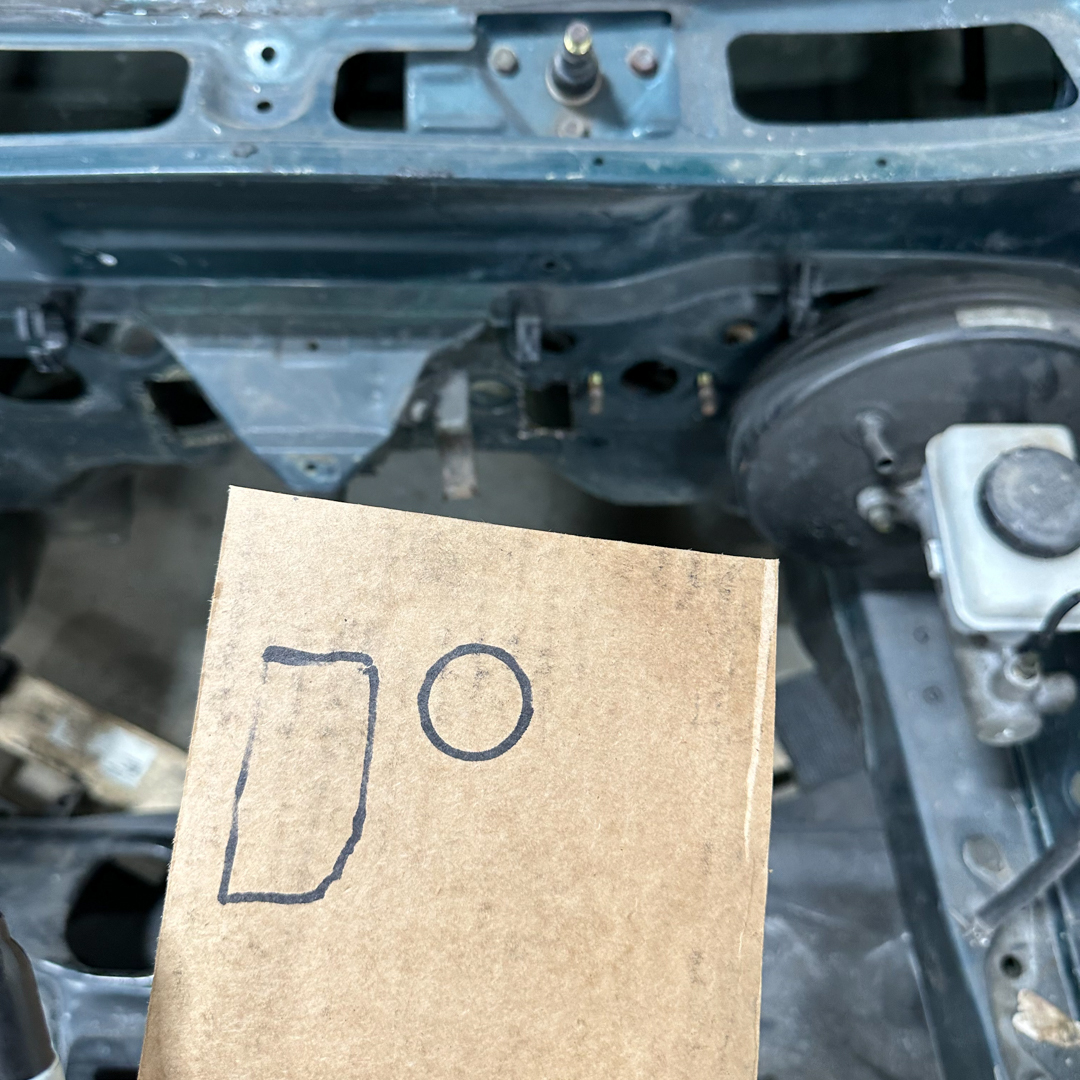

Then it was time for the main event, cutting the pieces out of the donor firewall to weld into the car. I started with a good ole CAD template, (ya know cardboard aided design?) then traced these onto the donor firewall and cut them out.

Next began the long process of test fitting, grinding the edge a bit, testing fitting again.. and so on, until the pieces fit in their holes. Admittedly, I could've done a better job minimizing the gaps, but that's what a MIG welder is for after all!

Overall I am satisfied with how they fit, and more importantly have a new found excitement to actually get some stuff done on this car!

Next step is to prep the surfaces on the firewall for welding, then we will move on to the modifications required to fit a facelift dash in a pre-facelift car.

Stay tuned for more updates soon!